Hey Everyone,

First:

Thank you to everyone that has reached out to me. Please do not hesitate to continue to reach out. I love hearing from you. Text me at 4082036130 (my personal phone number. Please be respectful and text at reasonable times because I am just one guy in an apartment and I run 5 other businesses).

Second Announcement:

Sorry to say, but we have another slight delay delay due to small tool changes to improve manufacturing. Starts shipping in early December. More on that below.

Third Announcement:

Again... I am not relying on your payment to fund the wheels. If you want a refund, please let me know. I’m not here to scam anyone. I just want to make a really awesome product and make innovations for the community but it does take some time.

Reasons for the delay:

- A lot of very small changes to improve mold life, mold alignment, ejection of wheel mold... stuff that you guys probably don't care about.

- Some aesthetic design changes

- One functional design change - incorporating wear markers

Lots of small CAD changes and going back and forth of the manufacturer proposing different options. Some that were not good and I felt would hurt durability. For those changes, I wouldn't let any changes to be made and as such we had to find other solutions, which took time.

All small tool changes which do not affect the durability or performance of the wheel

Example of mold improvement changes:

Before:

After:

As you can see very small changes to help with tool alignment and wheel ejection from mold. There were probably 4 other examples that are similar in other areas of the wheels. Let me know if you want to see those too.

Molded Aesthetic to the wheel:

Of course, this still shows the lettering molded, but that is what it will look similar to. The lettering won't be recessed, but it will be printed on instead.

Had to remove the recessed lettering

Initially, I was going to have the Logo molded, but apparently the lettering was too shallow and anymore deeper would compromise durability. So, I will have to stick to screen printing.

Wear Markers

There are four small dimples on the wheels - very tiny, about a 1mm wide by 3mm long and .5mm deep. These are wear indicators. Most people will just be cruising and it is just designed to tell you when you should replace the wheel as the diameter gets smaller over a long time. I have projected based on the prototypes and wear that it should get at least 2,000 miles.

Of course, it's not completely a perfect system because if you are carving a lot, it can take away the wear marker, but I think most of the time people will be going straight. Hopefully that makes sense.

Tooling progress

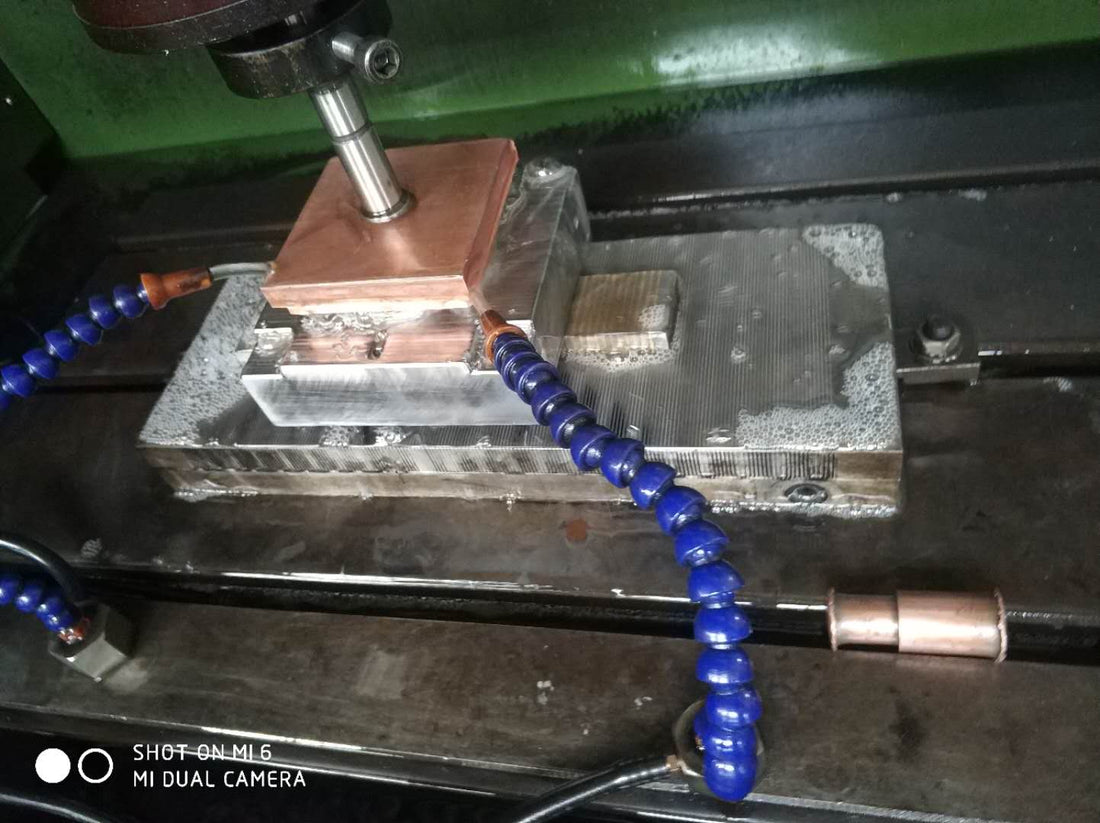

The injection molds are made through CNC for rough cutting and then finishing with EDM (Electrical discharge machining) used for high precision finishing. These photos are about 2 weeks old now and I have to go get more, but trying not to bother the manufacturer too much and letting them focus.

Finishing EDM on a mold

What exactly is EDM? No, not dance music but Electrical discharge machining, also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges.

Here is a cool video to show how accurate and precise EDM is. For the Hollow Wheel there are very tight tolerances on a lot of the parts where EDM is required, like the bearing bore, the surface interface between the core and the thread, and others.

EDM in action:

These are rough cuts of the core and the cover. About to get EDM machined.

Updated Timeline:

All-in-all, it is another 2 weeks of delay from the above changes. It hurts me as much as you do, believe me, but I want to make this right first.

Before:

New Timeline:

Some topics for the next update (about a week or so)

I have another update coming soon. Going to change the color a tiny bit. The TPU comes from the TPU factory completely clear and so I can make the core and the thread not opaque, but a smoked or tinted. It won't affect the performance because we just end up adding a little pigment. I'll post a pole on the next update. Getting tint samples and will take pictures of the tint and get people's thoughts. Can do any color.

The reason why I want to consider exploring going from Opaque to a smoked design is because, well, I personally think it could look cool, but there is an opportunity where I can incorporate lights into the inserts and then the wheels would glow at night.

How am I doing?

I am always looking for feedback on how you think this is going to I can address any concerns. Please let me know in this 5-10second google survey: https://forms.gle/hAzv7F7yV3RfXcqg7

Thanks,

Doug

6 comments

Take your time bro. You’ve a got my support all the way!