Hello everyone,

I think we are nearly at the finish line. Again, sorry for this embarrassingly long delay. For a recap on why I suck, there were a slew of delays but the longest was getting the injection molding process and materials to work together so that it would not delaminate. Hard to predict and hard to foresee. Also the test rig kept breaking itself, so I had to fix all the weak points. Nevertheless, I put on a lot of miles with the durability test rig and currently waiting on some news about next steps with the vendor. I am feeling cautiously confident about pulling the trigger for the first batch. More on that below.

I am doing a Facebook Live Ask Me Anything event today (3/3) at 730pm to 8pm. Here is the link. Of course, you can ask me anything at any time because you have my personal phone number (4082036130), you have my email (hello@momentum-boards.com), you have my Facebook (https://www.facebook.com/doug.hoang/).

I'll be at my shop and you'll be able to see the Hollow Wheels running on the testing rig. Unfortunately, I can't do it any sooner than that, but if this is something people want me to do again, I can do it again during this weekend.

In this update, I'll be focusing on durability and the science behind it and the next steps

Cliff Notes: Durability is nearly complete. I am waiting on the manufacturer to give me a timeline. The next steps are for me to get the balls to go ahead with a small batch, doing a little bit more testing to make sure quality can be upheld, then hopefully start shipping. My estimate is that it will take them 10-20 days to finish production, then I will make sure all quality processes are in check, then 10-20 days to ship to me. Then, I have to package everything and then ship to you.

Durability Target and Methodology

Target: The wheel must reach 2,000 miles.

Must avoid failure modes including, but not limited to:

-

Delamination between core and thread

-

Any Cracking

-

Excessive vibration; wheel is imbalanced

-

Flat spotting of soft TPU

-

Bearings falling out from core

-

Excessive bearing noise from bearings

-

Wheel wear must not be detriment to safe handling, general assembly, or function

Example of past failures:

-

Tread showing early signs of delamination from Core TPU (Look at Wheel with “C”): https://drive.google.com/file/d/1xWfmPFHTgcBwS3IaCJZvQnW-XHxAi1_R/view?usp=sharing

Testing Parameters

Simulating Cornering Forces: https://www.youtube.com/watch?v=oFD1YmMNIvY

-

Temperature: 130F

-

Mileage: 2,000 to be completed

-

We simulate at least a 300 lbs rider going over corners for 2,000 miles.

-

Must not exhibit any of the failure mechanisms shown above

-

Must test 10 individual wheels that show no failure for the design to pass to production. I am not currently at 10 individual wheels yet (only 4). More on that later.

Pot hole testing: https://www.youtube.com/watch?v=kdMgsfaJH8w

-

Temperature; 130F

-

Mileage: 2,000 to be completed

-

We simulate at least a 300 lbs going over pot holes at 130F for 2,000 miles:

-

Must test 10 individual wheels that show no failure for the design to pass to production. I am not currently at 10 individual wheels yet (only 4). More on that later.

This is a testing machine that simulates pot hole riding: https://www.youtube.com/watch?v=8H4zavx8XDc

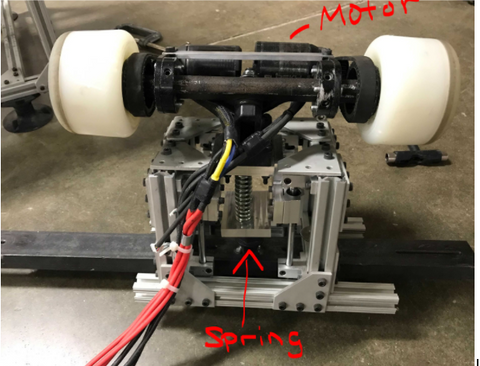

Figure 1: This is my testing machine where the wheels are attached to electric skateboard drivetrain.

Rapid Acceleration and braking repeated

-

Temperature; 130F

-

Mileage: 2,000 to be completed

-

We simulate at least a 300 lbs going over simulating rapid acceleration and braking at 130F for 2,000 miles.

-

This may be combined with the aforementioned tests above.

-

Must test 10 individual wheels that show no failure for the design to pass to production

What is this Test Rig Machine??

Designed to reduce durability testing time. Designed to simulate forces and temperature from real life.

-

Pothole impact forces

-

Cornering forces

-

Normal Riding forces

The machine has an electric skateboard drive train and has springs to simulate a rider of 500lbs (getting the test rig to rotate that at high speed is another story... Hint: doesn't really roll that well at high speeds).

High Impact Pothole Forces

The wheels and drive train are placed under a drum to simulate road forces. In this configuration, we test normal riding with radial forces placed on the wheel as well as shock testing from a pothole.

High Load Cornering Forces

The machine can also simulate high load corner forces. In other words, this can simulate when the rider is turning a corner very hard.

Rolling Road Resistance

The machine also places load on the core to simulate rolling road resistance as well. This is a picture of a motor which acts as a brake for the drum. Bonus points if you can guess what that motor is from.

Pothole and Radial Load Testing Method

The pothole testing is an example of a high accelerated life testing. A test is run at 35 mph, which means that the wheel is getting hit about 40 times per second. 35mph is the fastest I can go in this particular test because it turns out hitting a pothole 40 times a second makes it hard to travel much faster with the battery pack that I have (Thanks, Jansen!). This test is run for every 2 minutes and then checked. This means that every 2 minutes, the wheel takes a pothole hit 9,600 times every 2 minutes. The wheel is also heated to 130F. Then there is 2 minutes for inspection for failure. Then repeat till the wheel breaks.

So yes, I am brining the wheel to a point of failure. Now the question is... how do I correlate this to 2,000 miles? This is what is honestly confusing me.

Corner Load Testing Method

The corner load test is conducted at 50mph for 2 minutes at a time with 2 minutes for checking of failure. The wheel heats to 130F. The common failure to look out for is core delamination (see videos in the first page). I'm still running this test. Testing takes a lot of time.

Overall Testing Results (Preliminary)

Batch 1 of Samples: If you recall, this batch was too hard; the tread was too hard.

Testing: A couple of customers had ridden the shit out of this and there weren't any problems with it, but it was too hard, yet still better than a lot of competitor wheels. Though, not as good as the prototypes. I was not satisfied. Back for more iterations.

Because this was a harder wheel, there is less flex so the lack of core/tread delamination did not show it's ugly head.

Batch 2: Went softer on the tread.

Testing: Even higher approval rating, but now there was core delamination (see core delamination videos in first page). This is a risk. Had to change the tooling to eliminate delamination. No chemical adhesion.

Batch 3: Changed core tooling for more mechanical locking and better chemical adhesion. Also went softer on the tread. Changed a bunch of mechanical properties, materials, and injection molding settings.

-

Sample A: Softer tread and TPU core with new core modification to prevent delamination

-

Sample B: Softer (same as sample A) tread TPU and different core material with new core modification to prevent delamination

-

Sample C: Same hardness as batch 2 tread and different core material (same as Sample B in Batch 3) with new core modification with new core modification to prevent delamination

Results:

-

Sample B and C: Testing showed that core and tread still had delamination but this is because we chose a new material that would have high production efficiency but not great chemical adhesion properties. Originally thinking the new core modifications could make up for it. Didn't pan out.

-

Sample A: Testing showed this was an insanely comfortable and grippy wheel with no more preliminary delamination from the on going test rig testing. This one has lower production efficiency (higher cost) but excellent chemical adhesion. Might be too soft of tread where durability may be a concern... so commence on going testing (to this day).

-

Still conducting test rig pothole, radial load, and corning testing. Pothole testing to be completed by Saturday (3/6/21) with testing machine

-

Corner testing to be completed by 3/12/21 with testing machine

Batch 4 of samples: core material was changed again to improve production efficiency.

-

Sample A: Same as batch 2 tread with new revised core material to increase production efficiency (less scrap)

-

Sample B: Softer tread (in the middle between batch 2 and batch 3, sample A with new revised core material to increase production efficiency (less scrap)

Results:

-

Sample B: performed better than sample A, but slightly worse than Batch 3, sample B on rider comfort and grip

-

Still conducting test rig pothole, radial load, and corning testing. Pothole testing to be completed by Saturday (3/6/21) with testing machine

-

Corner testing to be completed by 3/14/21 with testing machine

So far Batch 3, sample A is the lead and durability testing is promising. I wanted to test a total of 10 individual wheels, but only have 4. But the 4 look good. So I am making a really big batch of wheels, which could go out. So this is where I am at. I think Batch 3, sample A is the winner so I am going to make a small bet.

I would be lying if I were not a little bit scared because I don't want to release a bad product and pull a Cloud Wheel, which would pretty much destroy this project. Thoughts?

This is where I am at. Hope to hear good news from the factory by tomorrow night. Sorry for typos.

Thanks for reading!

Doug

10 comments

Please just post some pics somewhere and pick the better of the 2. I hope you are keeping the metal “suspension poles” inside of the wheel And they slide in and out…. But after a big announcement and saying that your list thing you need to do to get these to mass production is to choose between A or B than PLEASE SHOW some PICS! I am interested if these are the same wheels that come apart??

100% agree. Everybody here has your back. You’re doing awesome by us. Take your time and do what you think is best.

:)

The longer I wait, the better it will be at the end. Patience is key!

Hi Doug, thanks for keeping us informed. No need to apologise for delays anymore, you already offered refunds for those inpatient buggers, so keep going. I think that sending a few for testing wheels to some people will give you and the public some relief that the product is really coming out and not under test for eternity :). Note that other manufacturers are also delaying deliveries at this time, for example it took me 10 months to get shark wheels delivered and they have been in the business for long time. So complete the test you will like to ensure safe wheels are delivered. Thanks for your effort and keep up the good work

The best or nothing.

This is the way.