Hey everyone,

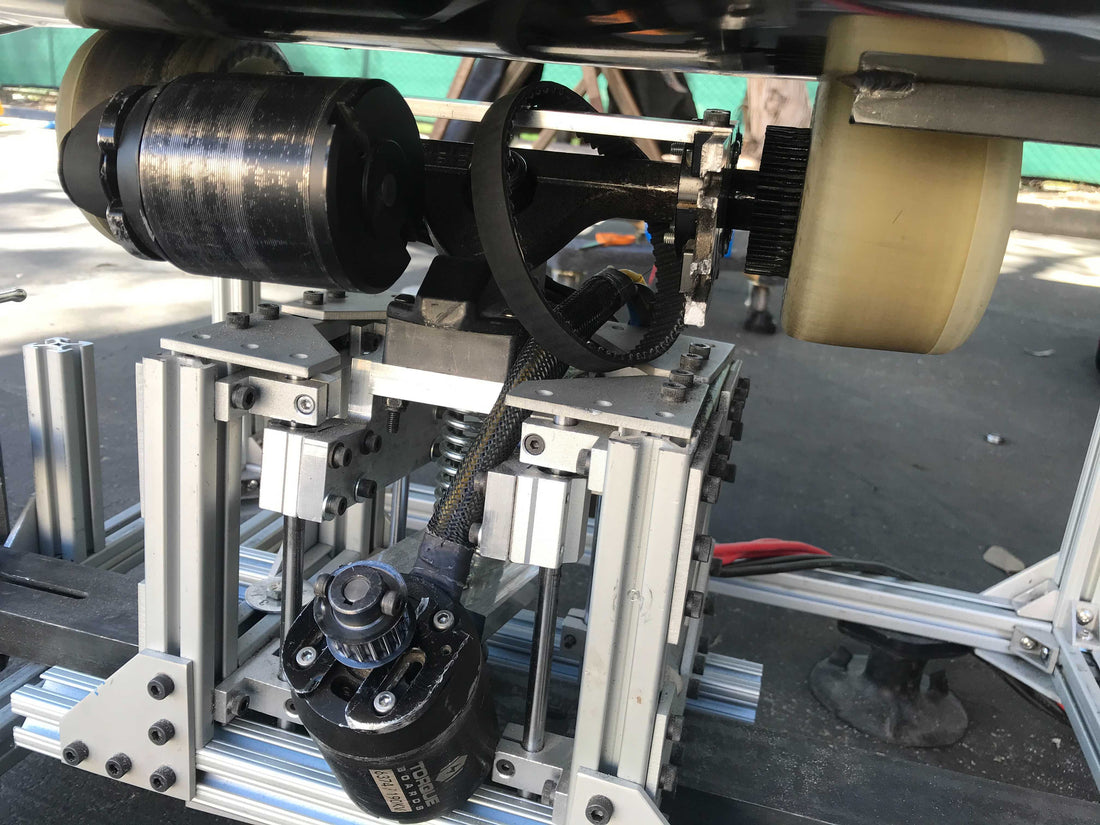

Quick update here. Had a delay on the durability testing. One of the motor mounts broke. The mount that drives the wheel for the pot hole testing. I think it had undergone 100,000 impacts or so, but it broke. So I have to wait on steel one. Luckily, someone (Shawn C) from the community had some steel motor mounts and they should be arriving in a couple of days to get me back up and running.

So tearing down and inspecting the test rig added a whole lot of time and set up to test lateral forces. So not all is lost, but it definitely added about 3 days of downtime and extra work. Today, I wasn't able to run the machine because I had to try to fix the test rig. Ugh.

Here is a quick video taken a couple of days ago:

Other news:

Many people are asking if they will be the first to be shipped to in the first 200 set batch, if mass testing goes well. Short answer is: If you're in the first batch, then high chance that you will. If you're in the 2nd batch, then there is a chance.

It is hard to say because I need to inspect these wheels very thoroughly and I will be destructive testing a lot of wheels. The current plan is to destructive test at least 50 sets, minimum. Destructive testing means they will be destroyed either in the testing process or in the after the test inspection (I have to cut them in half and look for signs of failure).

Why 50 sets minimum? It represents a statistically significant sample size wherein the numbers would indicate that it will yield hopefully a low warranty rate and most importantly a hopefully very safe wheel for everyone to ride on.

Why 200 sets in the first place? Well, I would have rather not order that many sets (I would have liked 50 sets) but the manufacturer needs to make some money on this, they can't do low volume, and I need more wheels to test at scale to make sure all our processes and the structure of the wheel is good. 200 is the lowest they could go. They deserve the money and it's the cost of doing business.

Timeline: The completion of the pot hole test due to the motor mount breaking is pushed off by about a week and a half (I said the 6th for completion, but that is pushed off till the 17th because of the repairs). Hopefully the new motor mounts are good. In the meantime, I am making progress on the lateral testing. I am gathering data and trying to make sense of it. The results are OK so far, but I have to think some more before I release my thoughts.

Please let me know if you have any thoughts. If you're getting too impatient (I get it and I am sorry for that), then feel free to get a refund.

Thanks,

Doug